About bronze sculpture casting process and maintenance

Copper sculptures mainly include bronze sculptures, bronze sculptures, and bronze sculptures.

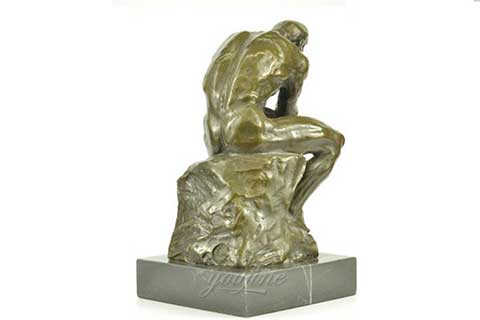

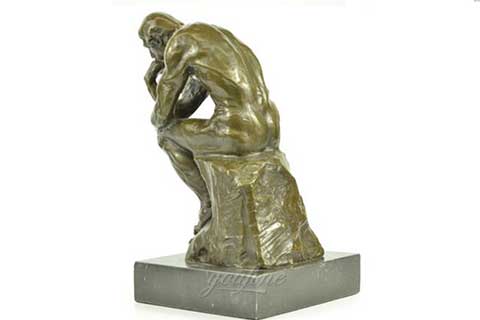

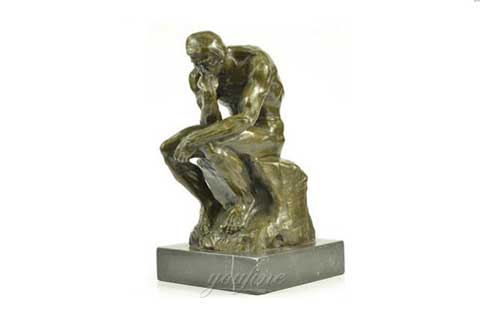

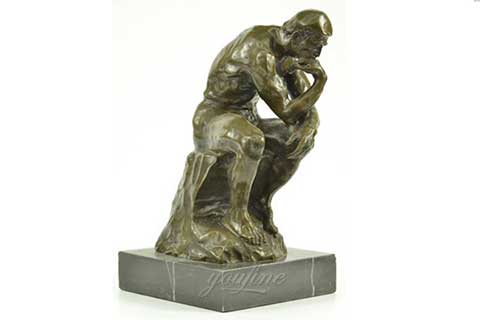

Cast bronze sculpture

The history of cast copper is very long and the casting technology is mature. The process of casting copper is more complicated than forging copper, and the restoration of artistic creation is good. Therefore, it is suitable for being a material of fine works, which is very popular among artists, especially character sculpture is the most common. But it is easy to oxidize, so pay more attention to maintenance.

Wrought bronze sculpture

The process of wrought copper sculpture is to first make a mold, and then use special glue to fix it in a fixed position. After the copper plate is heated, the soft and soft copper plate is placed on the mold and beat with a hammer. After hitting, it is restored toughness. It can be formed. If the copper plate is hardened, it can be heated repeatedly, but it is better not to do it more than three times. It should be immersed in the copper sulfate to make a work of art or other life and industrial products.

Copper sculpture

The main raw material of copper sculpture: copper. Copper is a simple substance of copper, named after its color is purple. See copper for various properties. Copper is an industrial pure copper with a melting point of 1083 ° C, no isomeric transformation, a relative density of 8.9, five times that of magnesium. It is about 15% heavier than ordinary steel. It has a rose red color and is purple after forming an oxide film on the surface, so it is generally called copper. It is a copper containing a certain amount of oxygen, and is also called oxygen-containing copper. The use of brass can produce a good quality copper sculpture.